13.25/2.06mm Phillips Screw: A Comprehensive Guide

The world of fasteners is vast and intricate, with a wide range of screws serving specific purposes. One such specialized screw is the 13.25/2.06mm Phillips Screw, which stands out due to its unique dimensions and utility in precision applications. This article will explore the characteristics, applications, benefits, and technical aspects of this screw while shedding light on its importance in various industries.

What is a 13.25/2.06mm Phillips Screw?

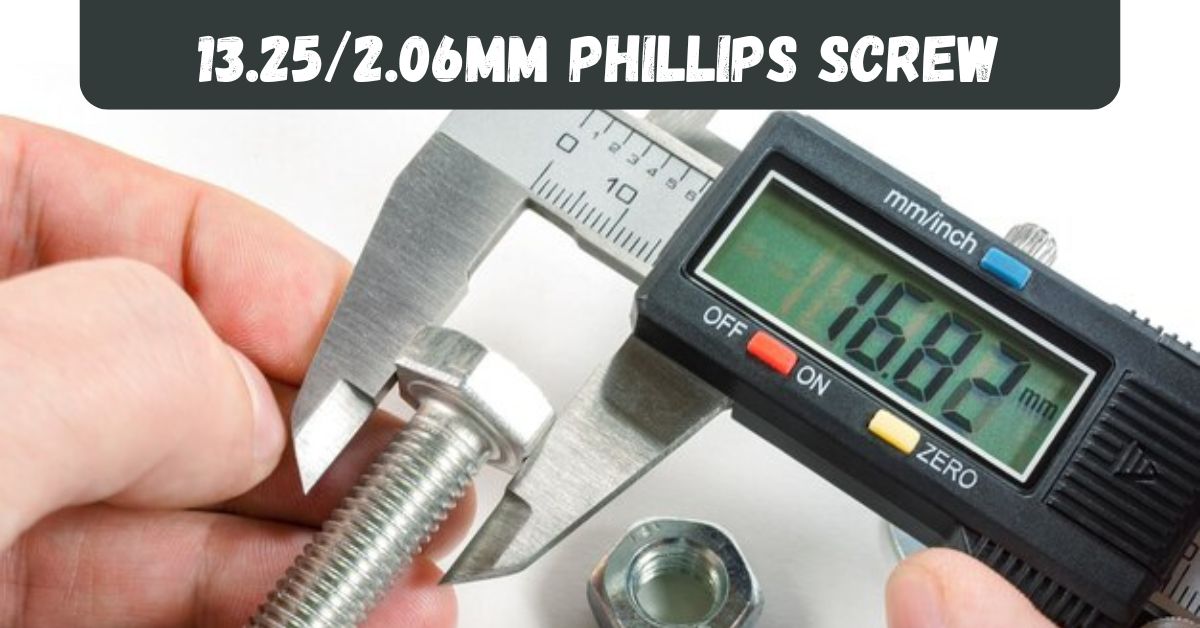

A 13.25/2.06mm Phillips Screw is a type of fastener that uses a Phillips drive system. The “13.25” refers to the overall length of the screw, measured in millimeters, while “2.06mm” represents the diameter of its shank. As a Phillips screw, it features a cross-shaped indentation on its head, designed for use with Phillips screwdrivers. This design allows for improved torque and ease of use compared to traditional slotted screws.

Due to its precise measurements, this screw is often utilized in applications requiring a balance of strength, stability, and compactness. Its design ensures it can provide a firm hold while maintaining a small profile, making it a popular choice in various industries.

Key Features of the 13.25/2.06mm Phillips Screw

The 13.25/2.06mm Phillips Screw is characterized by several features that make it unique. First, its precise dimensions allow for its use in applications requiring high levels of accuracy. The Phillips drive system ensures a secure grip during installation, reducing the likelihood of slippage or cam-out. This design also facilitates faster and more efficient fastening.

Another notable feature is its compatibility with a range of materials. Whether used with metals, plastics, or composites, this screw offers reliable performance and durability. Its size and design make it suitable for use in confined spaces where larger fasteners might be impractical.

The Importance of Precision in Fasteners

Fasteners like the 13.25/2.06mm Phillips Screw play a critical role in ensuring the stability and reliability of assembled components. In industries such as electronics, automotive manufacturing, and medical device production, the use of precisely measured screws is vital.

For instance, in the electronics sector, screws of this size are often used to assemble small devices like smartphones, laptops, and cameras. The accuracy of these screws ensures that delicate components remain securely fastened without the risk of damage. Similarly, in the automotive industry, they are used in dashboards, control panels, and other areas where space constraints demand compact fasteners.

Applications of the 13.25/2.06mm Phillips Screw

The versatility of the 13.25/2.06mm Phillips Screw makes it a preferred choice in numerous applications. It is commonly found in the following sectors:

- Electronics: The small size and precision of this screw make it ideal for assembling devices such as smartphones, tablets, and other compact gadgets.

- Automotive: In the automotive industry, these screws are used in areas where space is limited, such as dashboards, control panels, and electronic modules.

- Medical Devices: Medical equipment often relies on precision screws to secure delicate components. The 13.25/2.06mm Phillips Screw ensures a secure fit without compromising the integrity of the device.

- Aerospace: In aerospace applications, where weight and size are critical considerations, these screws are used to assemble intricate systems and components.

These applications highlight the screw’s versatility and its importance in various high-stakes environments.

Advantages of Using the 13.25/2.06mm Phillips Screw

The 13.25/2.06mm Phillips Screw offers several benefits, making it a valuable choice for manufacturers and engineers. Its small size allows for use in confined spaces, while its precise dimensions ensure a secure fit. The Phillips drive system minimizes the risk of slippage during installation, improving efficiency and reducing the potential for damage to the screw or the material being fastened.

Additionally, the screw’s compatibility with a range of materials increases its versatility. Whether used with metal, plastic, or composite materials, it provides consistent performance. Its corrosion-resistant properties further enhance its durability, making it suitable for use in challenging environments.

Materials and Manufacturing

The 13.25/2.06mm Phillips Screw is typically manufactured from high-quality materials such as stainless steel, carbon steel, or brass. These materials are chosen for their strength, durability, and resistance to corrosion. Stainless steel screws, for example, are ideal for applications where exposure to moisture or chemicals is a concern.

The manufacturing process involves precision machining to ensure that each screw meets the specified dimensions. This attention to detail is crucial for maintaining the screw’s reliability and performance in demanding applications.

Choosing the Right Screw for Your Needs

When selecting a screw, it is essential to consider factors such as size, material, and drive type. The 13.25/2.06mm Phillips Screw is an excellent choice for applications requiring precision and a compact design. However, it is important to ensure that the screw’s material and finish are compatible with the intended application.

For instance, if the screw will be used in an environment with high humidity or exposure to chemicals, a stainless steel version would be ideal. On the other hand, for applications where weight is a critical factor, a brass screw may be more suitable.

Maintenance and Replacement

While the 13.25/2.06mm Phillips Screw is designed for durability, regular maintenance is essential to ensure its continued performance. In applications where screws are subjected to frequent stress or environmental factors, periodic inspection is necessary to identify any signs of wear or corrosion.

When replacing screws, it is important to use the same size and type to maintain the integrity of the assembly. Substituting screws with incorrect dimensions or drive types can compromise the stability of the structure and increase the risk of failure.

Innovations in Screw Technology

The development of specialized screws like the 13.25/2.06mm Phillips Screw reflects ongoing advancements in fastener technology. Manufacturers are continually exploring new materials, coatings, and designs to enhance the performance and versatility of screws.

One notable innovation is the use of self-tapping and thread-locking screws, which simplify installation and improve reliability. These features reduce the need for additional tools or adhesives, making assembly faster and more efficient.

Conclusion

The 13.25/2.06mm Phillips Screw is a testament to the importance of precision in fastener technology. Its unique dimensions, reliable performance, and versatility make it an invaluable component in industries ranging from electronics to aerospace.

By understanding the characteristics and applications of this screw, manufacturers and engineers can make informed decisions that ensure the stability and durability of their assemblies. Whether used in high-tech devices or intricate machinery, the 13.25/2.06mm Phillips Screw exemplifies the critical role that small, well-designed components play in the modern world.