tsr messtechnik – mc 4.0 : Revolutionizing Measurement Technology

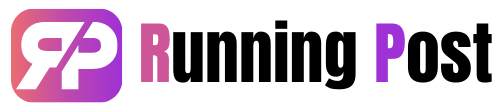

In today’s ever-evolving industrial landscape, precision and accuracy are non-negotiable when it comes to measurement technology. One name that consistently stands out in the field of advanced measurement solutions is TSR Messtechnik. The company has gained significant recognition for its cutting-edge products that address the challenges faced by industries requiring high-precision measurements. Among its innovative offerings is the MC 4.0, a technological marvel that has garnered attention for its capabilities in transforming measurement processes.

The TSR Messtechnik MC 4.0 represents a leap forward in the integration of modern technology into the measurement sector. It combines state-of-the-art features with robust performance to provide a solution that is both reliable and efficient. In this article, we will explore the MC 4.0 in-depth, uncovering its features, applications, and the impact it has on various industries.

What is tsr messtechnik – mc 4.0 ?

TSR Messtechnik is a leading company in the field of measurement technology. Based in Germany, TSR specializes in developing products and solutions that address the most demanding needs of industries such as manufacturing, automation, and research. The company has built a strong reputation for creating high-precision measurement instruments that deliver accurate and reliable results across a broad spectrum of applications.

The company’s focus on innovation and quality has made it a trusted partner for many businesses looking to enhance their measurement processes. tsr messtechnik – mc 4.0 offers a range of products, including sensors, gauges, and software solutions, each designed to meet the needs of various industries and provide users with the best possible measurement tools.

Introduction to MC 4.0: The Next Generation of Measurement Technology

The MC 4.0 is one of the standout products from tsr messtechnik – mc 4.0. It is part of the company’s commitment to pushing the boundaries of measurement technology. The MC 4.0 is designed to provide more than just precise measurements; it aims to streamline the entire measurement process, from data acquisition to analysis and reporting.

The “4.0” in the MC 4.0 name indicates its alignment with Industry 4.0, the fourth industrial revolution. Industry 4.0 is characterized by the integration of digital technologies into manufacturing processes, resulting in smarter and more efficient systems. The MC 4.0 is built with this philosophy in mind, incorporating advanced features that allow for seamless connectivity, real-time data analysis, and improved decision-making.

Key Features of tsr messtechnik – mc 4.0

The MC 4.0 boasts several key features that set it apart from traditional measurement tools. One of its primary strengths lies in its versatility and adaptability, making it suitable for a wide range of applications across various industries. Here are some of the standout features:

- Connectivity and Integration

The MC 4.0 is designed to seamlessly integrate with existing systems and infrastructure. It supports multiple communication protocols, enabling it to connect to different devices and software platforms. This flexibility ensures that the MC 4.0 can be easily incorporated into any industrial environment, whether it’s for small-scale operations or large-scale automation systems. - Real-Time Data Monitoring and Analysis

The MC 4.0 provides real-time data monitoring, allowing users to track measurements as they are being taken. This capability is crucial for applications where immediate feedback is required to make informed decisions. With its built-in data analysis tools, the MC 4.0 can process and analyze data on the fly, providing users with actionable insights that can optimize production and reduce errors. - High Precision and Accuracy

When it comes to measurement technology, precision is paramount. The MC 4.0 delivers exceptional accuracy, ensuring that every measurement is reliable and consistent. This high level of precision makes it ideal for applications where even the smallest discrepancies can lead to significant issues. - User-Friendly Interface

Despite its advanced capabilities, the MC 4.0 is designed with the user in mind. It features an intuitive interface that makes it easy to set up, operate, and monitor. Whether you’re an experienced technician or a novice, the MC 4.0’s user-friendly design ensures that you can maximize its potential without the need for extensive training. - Scalability

The MC 4.0 is highly scalable, making it suitable for businesses of all sizes. Whether you need a single device or a network of connected measurement instruments, the MC 4.0 can easily scale to meet your requirements. This scalability ensures that the MC 4.0 can grow with your business and adapt to your changing needs. - Data Security

In an age where data security is more important than ever, the MC 4.0 comes equipped with robust security features. It ensures that all data collected is stored securely, preventing unauthorized access and ensuring compliance with industry standards.

Applications of tsr messtechnik – mc 4.0

The versatility of the MC 4.0 means that it can be used in a wide range of industries. Some of the key sectors where the MC 4.0 is making a significant impact include:

Manufacturing

In the manufacturing industry, precision is critical for maintaining product quality and minimizing defects. The MC 4.0 is widely used in quality control processes to measure and monitor various parameters, such as dimensions, weight, and pressure. Its real-time monitoring and data analysis capabilities ensure that any deviations from desired standards can be detected early, allowing manufacturers to take corrective actions before defects occur.

Automation and Robotics

The MC 4.0 is also a valuable tool in automation and robotics. It can be integrated into robotic systems to provide accurate measurements for tasks such as assembly, inspection, and calibration. The ability to monitor measurements in real time allows for greater control over automated processes, improving efficiency and reducing the risk of errors.

Research and Development

In research and development, the MC 4.0 is used to gather precise data for experiments and prototypes. Its high accuracy and flexibility make it an essential tool for R&D teams working on projects that require exact measurements. Whether it’s testing new materials, developing new technologies, or conducting experiments, the MC 4.0 ensures that the data collected is reliable and reproducible.

Aerospace and Automotive Industries

The aerospace and automotive industries demand the highest level of precision when it comes to measurements. The MC 4.0 is used extensively in these industries to measure critical components such as engine parts, fuel systems, and structural components. Its ability to deliver precise measurements ensures that the parts produced meet the stringent safety and performance standards required in these industries.

The Impact of tsr messtechnik – mc 4.0 on Industry 4.0

The introduction of the MC 4.0 is a perfect example of how Industry 4.0 is transforming traditional industries. Industry 4.0 is characterized by the fusion of the physical and digital worlds, and the MC 4.0 plays a crucial role in this transformation by enabling real-time data collection, analysis, and feedback loops. By leveraging the power of the Internet of Things (IoT), cloud computing, and advanced analytics, the MC 4.0 helps companies optimize their operations and make data-driven decisions.

With its connectivity and integration capabilities, the MC 4.0 allows companies to create smarter manufacturing environments where machines, sensors, and systems can communicate and collaborate seamlessly. This interconnectedness leads to greater efficiency, reduced downtime, and improved product quality, all of which are key benefits of Industry 4.0.

Future Developments in TSR Messtechnik’s Measurement Technology

The MC 4.0 is just the beginning for TSR Messtechnik. As the company continues to innovate, we can expect even more advanced measurement solutions that will push the boundaries of what is possible in the world of measurement technology. Future developments may include even greater integration with AI and machine learning, enabling the MC 4.0 and similar devices to make autonomous decisions based on data analysis.

Moreover, as industries increasingly adopt IoT devices and smart sensors, we can expect the MC 4.0 to evolve further, with more advanced connectivity options and compatibility with emerging technologies. This ongoing innovation ensures that tsr messtechnik – mc 4.0 remains at the forefront of the measurement technology industry.

Conclusion: The Future of Precision Measurement with tsr messtechnik – mc 4.0

The tsr messtechnik – mc 4.0 is more than just a measurement device; it represents the future of precision measurement technology. By integrating cutting-edge features such as real-time data monitoring, advanced analytics, and seamless connectivity, the MC 4.0 is helping businesses across various industries optimize their processes, improve product quality, and make smarter decisions.

As we continue to embrace the principles of Industry 4.0, tools like the MC 4.0 will play an increasingly important role in shaping the future of manufacturing, automation, and research. With its unmatched precision and versatility, the MC 4.0 is poised to remain a key player in the measurement technology landscape for years to come.

For businesses looking to enhance their measurement processes and stay ahead of the competition, adopting solutions like the MC 4.0 is a step in the right direction. Whether you are in manufacturing, robotics, R&D, or any other industry that requires high-precision measurements, the MC 4.0 offers the tools and capabilities needed to thrive in the digital age.

Read More : Understanding Adsy.pw/hb5: A Comprehensive Guide